05.03.2026

Tele-Fonika Kable Signs Long-Term Agreement with @Alliander

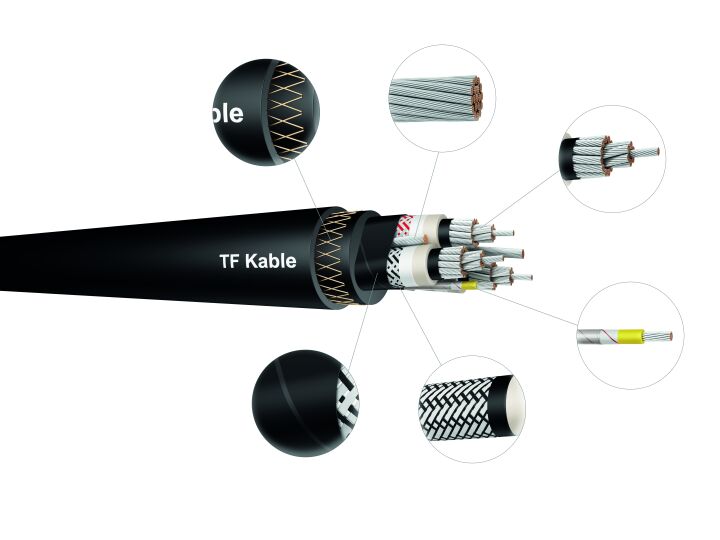

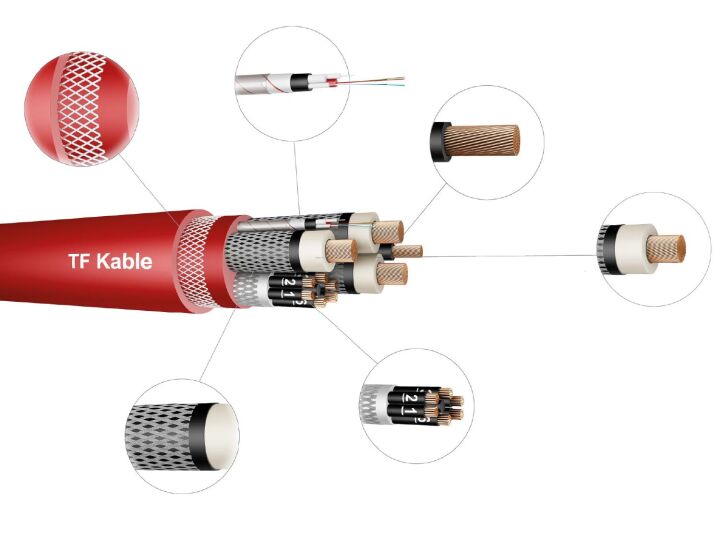

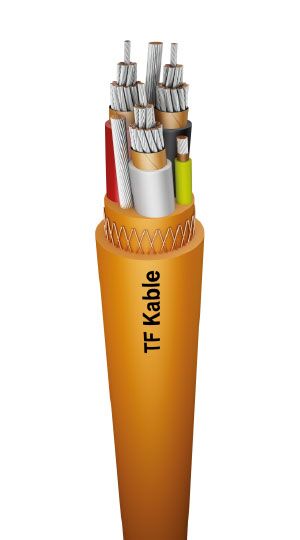

Tele-Fonika Kable has signed an eight-year framework agreement with @Alliander, one of the leading distribution network operators in the Netherlands. The partnership covers the supply of medium-voltage cables manufactured at the company’s Bydgoszcz facility, further strengthening Tele-Fonika Kable’s position within the European power distribution supply chain.

This is the second contract between the parties in recent years. Tele-Fonika Kable is currently supplying low-voltage cables under an existing agreement, reflecting continued cooperation and long-term trust.

Under the new framework agreement, products will be supplied directly to Alliander’s warehouses, ensuring continuity, reliability, and resilience across the Dutch electricity supply chain.

The cooperation follows a comprehensive and technically demanding tender procedure, which required full type testing and detailed validation of manufacturing capabilities, quality systems, and supply chain robustness. The process confirmed Tele-Fonika Kable’s operational reliability, technical expertise, and strong integration within the European power distribution value chain.

The partnership places particular emphasis on environmental performance, including carbon footprint reduction, recycling requirements, and enhanced product transparency.

In addition, Tele-Fonika Kable has been qualified as a supplier of 1 kV cables and has signed a framework agreement enabling future supply subject to demand.

This long-term cooperation further reinforces Tele-Fonika Kable’s role as a trusted and reliable partner supporting the Dutch energy transition, while maintaining a strong focus on sustainability objectives.

#TFKable #Alliander #EnergyTransition #PowerDistribution #SupplyChain #MediumVoltage #Sustainability #ESG #BydgoszczPlant

Go to our LinkedIn profile